Understanding Helicopter Parts and Components

Taking to the skies on a helicopter tour offers unparalleled views and the excitement of vertical flight. At the heart of this experience are the complex and intricate parts and components that make up the helicopter. A basic understanding of these components can enhance the appreciation of the tour and provide a glimpse into the marvels of aviation engineering.

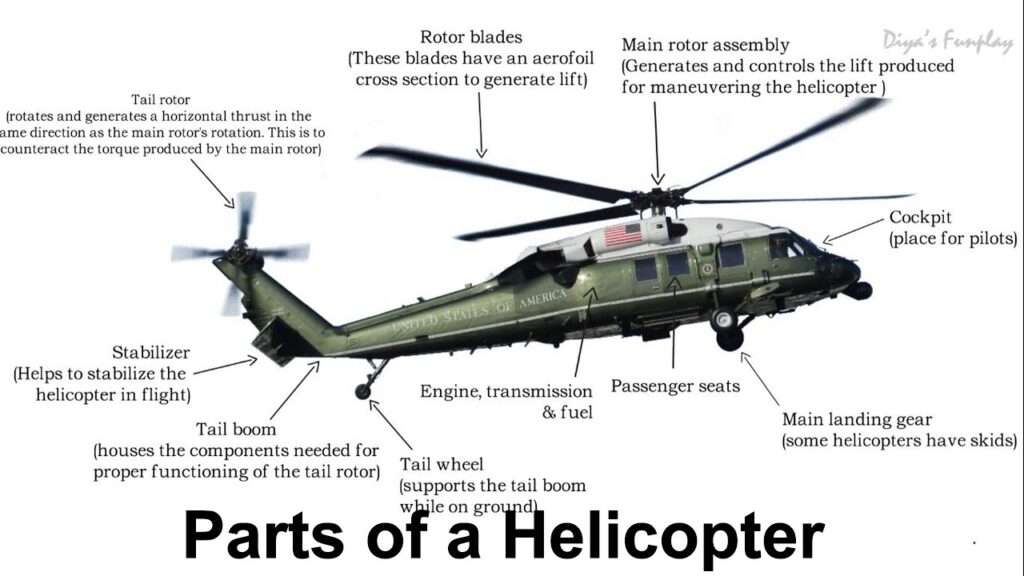

Main Rotor System

The main rotor system is the most prominent feature of a helicopter, consisting of several blades attached to a rotating mast. It’s the whirling power that provides lift and allows the helicopter to hover, move, and turn in any direction. The pitch of the blades can be adjusted to control the amount of lift generated, a unique characteristic that distinguishes helicopters from other aircraft.

Fuselage and Tail Boom

The fuselage is the central body of the helicopter, housing the cockpit, passenger compartment, and engine. Connected to the fuselage is the tail boom, a long slender structure that adds stability and holds the tail rotor. The tail rotor compensates for the torque effect of the main rotor and allows the pilot to steer the helicopter laterally, which is essential for precise navigations required during scenic tours.

Transmission and Engine

The engine is the powerhouse of the helicopter, typically located above the cabin. It drives the main and tail rotors through a series of shafts and gears known as the transmission system. This system efficiently transfers the power generated by the engine to the rotors, enabling them to spin at high speeds necessary for flight.

Avionics

Helicopters are equipped with sophisticated avionics that aid in navigation, communication, and flight control. Instruments like GPS, altimeters, and communication radios are crucial for pilots to safely conduct tours under various weather conditions. The cockpit, with its array of controls and gauges, is the command center where pilots monitor these critical systems to ensure a smooth and enjoyable aerial journey for all passengers.

The Importance of Regular Maintenance for Helicopter Parts

Ensuring the safety and reliability of helicopter tours relies heavily on the condition of the aircraft itself. The routine, systematic inspection, and necessary replacement or repair of helicopter parts are indispensable aspects of aircraft upkeep. It’s this regular maintenance that guarantees the smooth functioning of every flight component, instrumental in averting potential accidents or emergency landings which can be the result of part failure during flight.

Maintenance of helicopter parts is not only about safety but also about optimizing flight performance. Helicopter rotors and engines, for example, are under constant stress during flights, and even the slightest imbalance or wear and tear could lead to decreased performance. Regular check-ups ensure that these critical components are operating at their best, providing passengers with the smoothest and most efficient experience possible.

Additionally, keeping helicopter parts well-maintained plays a significant role in the long-term cost management of operating tour services. Preventative maintenance can often identify minor issues before they develop into major problems that could necessitate expensive repairs or replacements. Furthermore, helicopters that are serviced regularly tend to have higher resale values, which is an essential factor for tour operators to consider for their fleet management strategy.

Beyond the immediate concerns of performance and cost, regulations in the aviation industry make the routine maintenance of helicopters a legal requirement. Authorities like the Federal Aviation Administration (FAA) in the USA mandate strict adherence to maintenance schedules, and failure to comply can lead to fines or even groundings. Regular, documented maintenance assures compliance with these regulations and allows tour operators to avoid legal and financial penalties.

The longevity of helicopters is also directly tied to the frequency and thoroughness of their maintenance. When every part, from the smallest bolt to the main rotor assembly, is checked and kept in optimal condition, the overall lifespan of the aircraft is extended. This level of care and attention ensures that helicopters can continue to provide thrilling aerial experiences to tourists for many years, maximizing the investment made in each aircraft.

Innovations in Helicopter Parts and Their Impact on Safety

The ever-evolving landscape of helicopter technology has seen numerous advancements that have significantly bolstered the safety of these versatile aircraft. One of the most notable improvements is the advent of crash-resistant fuel systems. These are designed to minimize the risk of fires following a hard landing or collision, greatly improving the survivability of accidents. Such innovations in the fuel system are now increasingly becoming a standard requirement for new helicopters to ensure the highest level of safety for both passengers and pilots.

Another critical component that has undergone considerable refinement is the health and usage monitoring systems (HUMS). These sophisticated technologies continuously collect and analyze data from various parts of the helicopter, allowing for the early detection of potential mechanical issues before they lead to a failure. By predicting maintenance needs, HUMS play a pivotal role in preventing accidents and maintaining the integrity of the aircraft throughout its operational lifespan.

Furthermore, advancements in rotorcraft blade design have contributed to not only increased aerodynamic efficiency but also reduced noise and vibration levels. Materials like carbon fiber composites are now commonly used to construct more resilient and lightweight blades, contributing to better overall handling and stability of the helicopter. Such improvements are crucial for enhancing safety, especially during critical flight operations such as emergency medical services or search and rescue missions where stable and precise flying is paramount.

How to Choose Quality Replacement Parts for Your Helicopter

Choosing the right replacement parts for your helicopter is crucial for maintaining its performance and ensuring safety during your tours. When it comes to rotary-wing aircraft, every component plays a critical role in the overall functionality and reliability of your helicopter. To begin with, always consider the pedigree of the parts you are purchasing. It’s highly recommended to buy OEM (Original Equipment Manufacturer) parts whenever possible. These parts are produced by the same manufacturer as the original equipment, ensuring compatibility and reliability. They are designed to match the exact specifications of your helicopter, which means they will fit perfectly and function as intended.

Furthermore, the certification of replacement parts is an aspect that cannot be overlooked. Look for parts that have been certified by the Federal Aviation Administration (FAA) or equivalent regulatory bodies. These certifications confirm that the parts have passed rigorous testing and adhere to the strict standards set for aviation components. FAA-certified parts guarantee that the components meet high safety and performance criteria, which is particularly important when you’re responsible for the lives of your passengers during scenic helicopter tours.

Also, consider the reputation and reviews of the parts suppliers. In the aviation industry, reputation speaks volumes. Reputable suppliers will have established a track record of supplying high-quality parts and are more likely to provide comprehensive post-purchase support. It is beneficial to research and read testimonials from other helicopter operators to understand the quality of service and parts they received. Assuring the parts purchased are backed by warranties can go a long way in providing peace of mind.

Last but not least, factor in the total lifetime cost of the replacement parts. While it may be tempting to go for cheaper alternatives, they often result in more expenses over time due to shorter lifespans and more frequent replacements. Quality parts might entail a higher initial investment, but their durability and performance can lead to cost savings in the long run. When calculating costs, take into account the expected lifespan, warranty, and any potential for reduced maintenance and downtime—which translate into more flying time for your helicopter tours.

Key Helicopter Parts to Inspect Before Every Flight

Before a helicopter touches the skies, it’s essential for pilots and maintenance crews to perform thorough inspections to ensure every flight is safe and incident-free. One critical component to check is the rotor system, which includes both the main rotor and tail rotor. These rotors are vital for a helicopter’s lift, thrust, and control. Pilots should look for any signs of damage like cracks or excessive wear, and make sure that all rotor blades are securely fastened and free of debris that could impact their aerodynamic performance.

Another key part of a pre-flight checklist is examining the engine and transmission system. The engine is the heart of the helicopter, and a complete evaluation of its condition is necessary to prevent in-flight failures. This includes inspecting for leaks, ensuring that the fuel system is free of contaminants, and checking for any abnormalities in the transmission components that could signal potential issues. It is also important to verify that the oil levels are within the recommended ranges and that all filters are clean.

The flight control system also requires careful attention. The controls should move smoothly without any obstruction or unusual resistance. Ensuring the cyclic and collective controls are functioning correctly is paramount as they are directly responsible for the helicopter’s maneuvering during flight. Additionally, the condition of the anti-torque pedals, which control the direction of the helicopter, should be rigorously tested for responsiveness and reliability. All linkages and joints in the control system must be inspected for integrity and proper lubrication to prevent any in-flight control issues.

The Role of Helicopter Parts in Enhancing Flight Performance

Helicopter performance is crucial for ensuring safety and efficiency during flight tours across the USA. Every part of a helicopter plays a significant role in its overall flight performance. Components such as the rotor system, engine, and aerodynamic design are meticulously engineered to work in harmony, allowing the helicopter to achieve lift, maintain stability, and navigate the skies with precision. Understanding how these parts interact is essential for appreciating the capabilities and limitations of different helicopter models used in tours.

The rotor system, which includes the main rotor and tail rotor, is fundamental to a helicopter’s ability to lift off the ground and move in different directions. The main rotor provides the necessary lift by pushing air downwards, which in return lifts the helicopter up. Meanwhile, the tail rotor compensates for the torque effect and provides directional control. Enhanced materials and design in these rotors have led to improvements in efficiency and noise reduction, enabling a quieter, more comfortable experience for passengers on their scenic flights.

Another critical component is the helicopter’s engine. The engine’s performance directly impacts the helicopter’s ability to reach higher altitudes and speeds. With advancements in engine technology, tour helicopters now feature more powerful and reliable engines that can perform in a range of conditions. This is especially important in the diverse landscapes of the USA, where flights may encounter various climates and altitudes, from the hot and arid deserts to the cold and windy mountains.

Aerodynamics also play a significant role in flight performance. The body of the helicopter is designed to minimize air resistance and maximize efficiency. Enhanced aerodynamic designs contribute to a smoother and faster ride, crucial for maintaining a tight tour schedule. Features like streamlined fuselage, optimized rotor blades, and advanced stabilizing systems ensure that helicopter tours offer both thrilling views and a stable platform from which to enjoy them, highlighting the delicate balance between performance and passenger comfort.